The Fairmat Ecosystem

This is where the revolution begins.

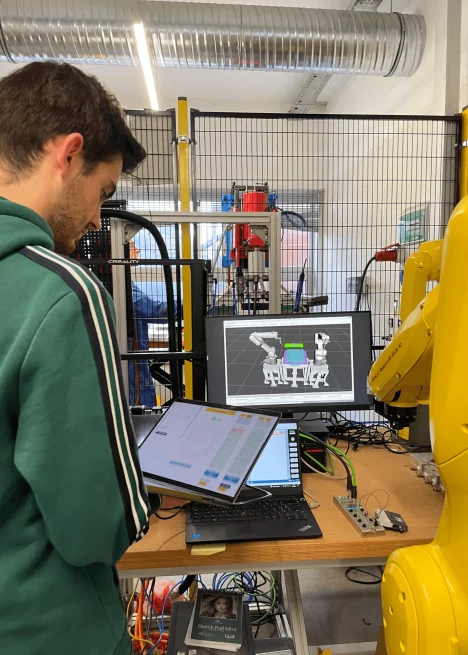

Research and Development

Our Research and Development Lab is dedicated to advancing the field of deeptech recycling and material science, particularly focusing on carbon composites. Strategically located in Paris, our facility is equipped with cutting-edge technology and staffed by a team of highly skilled product developers, robotic engineers, software programmers, researchers and material scientists.

Our R&D Lab is committed to:

Pioneering Research

Leading groundbreaking research to enhance the efficiency and sustainability of advanced recycled materials

Collaborative Efforts

Partnering with industry leaders and forward-thinking partners to drive innovation and ensure our solutions meet real-world needs.

Innovative Solutions

Developing novel methods and technologies to transform carbon composite waste into high-value materials for various applications.

Sustainability Focus

Emphasizing environmentally friendly practices to contribute to a circular economy and reduce the carbon footprint of industries.

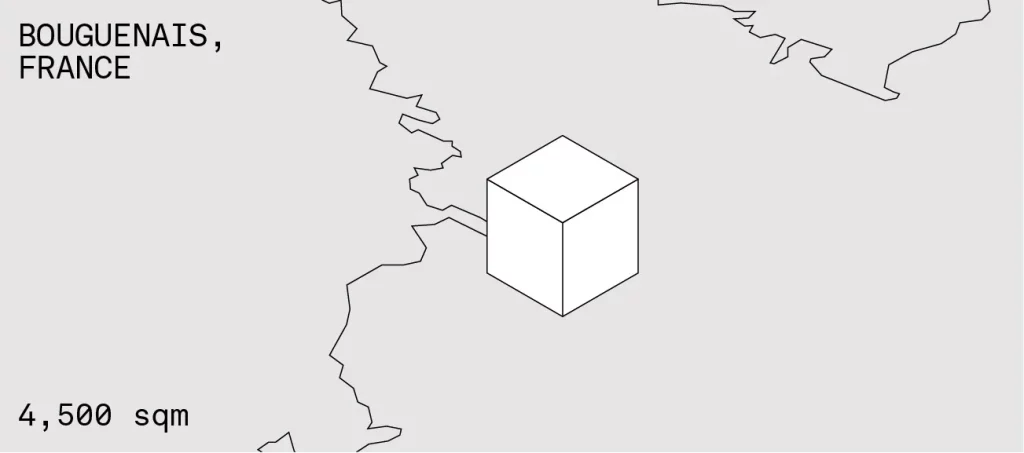

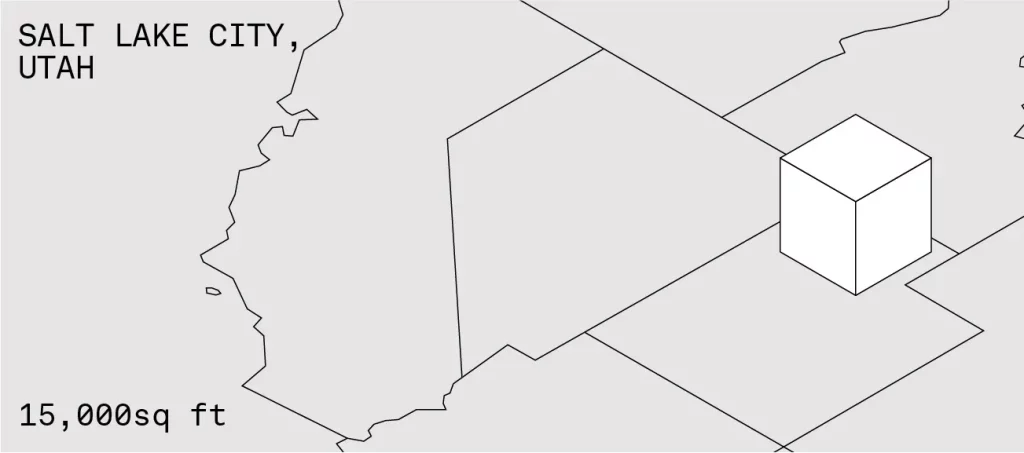

Two Connected Factories

Integral to the Fairmat Ecosystem are two state-of-the-art, interconnected factories, the backbone of our closed-loop technology, dedicated to recycling carbon fiber and manufacturing high-quality laminates and parts for our clients.

France

United States

End to end solution from waste to product